DISTRIBUTION CENTER IMPLEMENTATION

Start Your Distribution Center on Time and on Budget

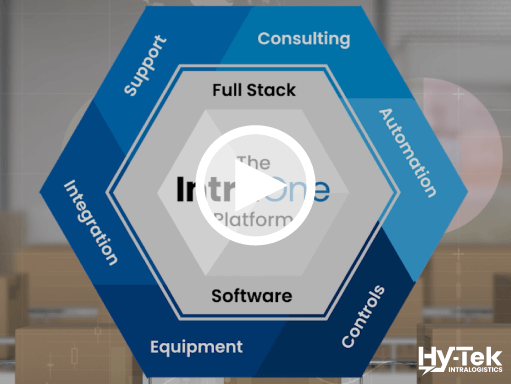

Operations improvement can be elusive. For example, when engineers or consultants propose process changes and improved automation for your facilities, there is no guarantee that the changes will enable greater efficiency. Our consultants and engineers provide a complete analysis of your existing situation. Then we provide you with data tools and deep supplier connections, offer material handling techniques, examine employee screening and training, and highlight flow patterns. We also work alongside you through project execution to ensure that your goals are met so you have confidence in the long-term results of these changes.

How We Can Help

MHE Specifications

We give you MHE specifications for each subsystem within the facility. These detail the length, width, height, type, load capacity, guarding, sequencing, and controls for each component to ensure that each prospective MHE supplier will have the appropriate information to satisfy the facility requirements for the equipment offered.

MHE Implementation Management

We ensure project requirements are satisfied throughout the installment and startup of your facility. Weekly project communication meetings maintain an open dialogue for all parties involved and keep the project on schedule. Upon the completion of the MHE installation, formal acceptance testing is conducted and documented.

Supplier Proposal & Selection

The Request for Proposal details the deadlines, business requirements, and equipment specifications. After reviewing all proposals we provide a decision-making scorecard that integrates quantitative and subjective decision criteria through a weighted scoring exercise to land on a recommendation of the best value and best fit MHE supplier for each project.

Facility Construction Management

Take advantage of tax credits, employee screening, training assistance, federal and state incentives, and more to get the most out of your site location.