The “warehouse of the future” concept is a little nebulous without a clear definition of what is meant by “the future.” Without a crystal ball, it’s hard to imagine what the future might look like in say…100 years.

Some people would argue that the future is now considering that technologies like robotic goods-to-person picking systems and robotic piece picking are being implemented today. Other people would probably picture the warehouse of the future to be a “lights out” facility where only machines are present.

In fact, both arguments are correct. The common denominator is that technology is constantly changing, allowing for improvements in warehouse operations, productivity, safety, and efficiency that are being implemented today and will only increase in the future.

Evolution of Warehousing Technology – What are the driving factors for change?

Making changes to any operation typically costs money, and businesses don’t like spending money unless it provides a benefit or becomes a requirement to remain competitive.

Warehousing has come a long way since its early days. Traditional warehousing 50 years ago was more focused on managing bulk transactions of pallets and/or cases.

As warehouse digitalization becomes more popular, there’s been a shift in how warehouses are managed and run. Automation, robotics, and AI-driven systems are changing the landscape of warehousing drastically.

Warehousing has changed to provide specific value-added services.

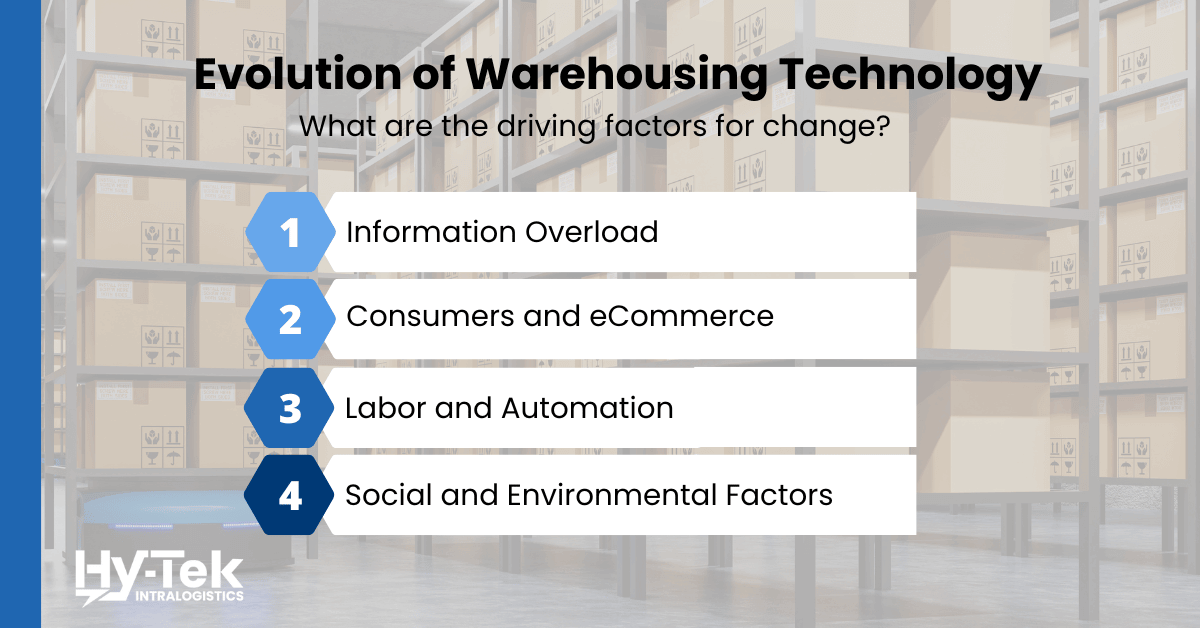

There are several market forces at work today that have accelerated the drive towards the more sophisticated warehouse of the future.

These market forces have created the requirement for change, but the result is the benefit of more efficient processes. Listed below are some of the key drivers guiding these changes:

– Information Overload

There is so much complex data available that it’s difficult to process and visualize using traditional methods. Previously, companies extracted only essential and easily analyzable data, overlooking valuable insights from “dark data“ for cost reduction, warehouse operations, root cause analysis, and decision-making improvements.

– Consumers and eCommerce

A report by Forrester predicts that online retail sales will reach $1.6 Trillion by 2027 – well above 2021’s $960.44 billion as reported by Digital Commerce 360. The need for immediate access to products, and shopping 24/7, has forced supply chains and the warehousing industry to adapt. Flexibility, responsiveness, and accuracy is the base function of any high-performing fulfillment business.

– Labor and Automation

A shrinking labor pool coupled with the increasing activity brought on by eCommerce growth, distribution centers are now forced to take a hard look at automating processes previously done manually.

– Social and Environmental Factors

Increasing consumer awareness of climate change is pressuring producers and distributors to be more socially responsible. Having smaller distribution centers near consumers reduces carbon emissions from long transit routes. Local sourcing cuts emissions compared to goods produced farther away. Implementing labor-saving technology in future distribution centers reduces environmental impact. Advancements may include lights-out facilities, reducing the need for lighting and temperature control, and taller buildings to minimize the footprint.

The next 50 years will see common adoption of technology in the warehouse. Refinements and innovation will continue. At some point, the supply chain will integrate manufacturing, packaging, and fulfillment into a seamless process where true “lights out” operations will be the norm, and “on-demand” warehousing will become more commonplace as technology improves.

Smart Warehousing – What is it and how will it evolve?

As our business landscape evolves and changes, there is greater pressure from the customer to ensure that just-in-time is not only met but that it is the expectation moving forward. Smart warehousing will be a pillar to support this evolution of customer demand. The days of shipping items within days and weeks are no longer acceptable in today’s market.

Smart warehousing utilizes a comprehensive and complex set of tools to help manage and streamline the overall fulfillment and warehousing operations.

Predicated on data analytics, smart warehouses leverage next-gen solutions that enable better decision-making, reduce overall operational costs, and allow you to be fully integrated to ensure internal processes are as efficient as possible.

Data analysis allows an operation to have a granular view of the entire operation so that you can make informed decisions as it relates to labor, inventory management, shipment demands, etc.

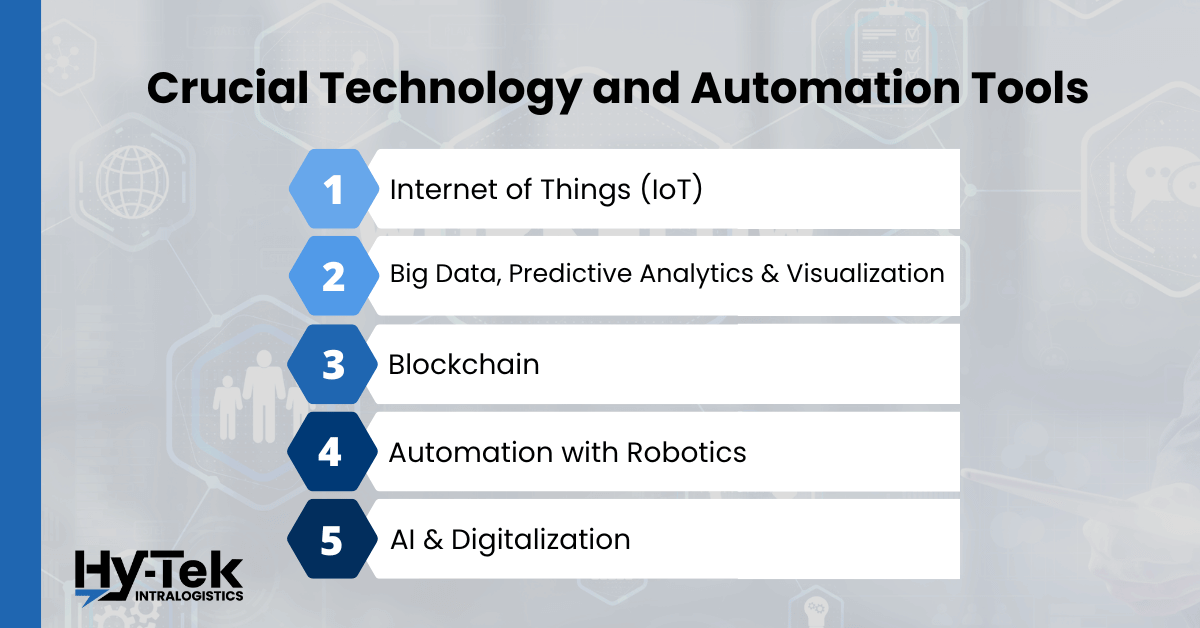

Crucial Technology and Automation Tools for Future Warehousing

In the rapidly evolving landscape of warehousing, the utilization of technology and automation tools has become imperative for businesses aiming to stay competitive and maximize efficiency.

By leveraging technology and automation, warehouses can optimize inventory management, improve order fulfillment accuracy, reduce operational costs, and create a seamless workflow. Embracing these tools is not just a matter of convenience, but a strategic investment that enables businesses to thrive in the future of warehousing.

Internet of Things (IoT)

The implementation of Internet of Things will only expand as all processes, technologies, sensors, products, and infrastructure within the warehouse ultimately connect and communicate with each other. This communication will allow for better coordination between inter-connected processes to maximize product flow and resource utilization but will result in a tremendous amount of data traffic that must be managed and secured.

This will be one of the roles that the expanded warehouse management systems of the future will be responsible for; comparable to the orchestra leader making certain all the musicians are in harmony.

The security of this data traveling across wireless channels will be of the utmost importance which will accelerate the implementation of more secure networks such as 5G cellular technology.

Big Data, Predictive Analytics, and Visualization

Big data refers to voluminous and complex data that is challenging to process using traditional methods. Advances in retrieval and storage enable the collection and analysis of this data. It encompasses volume, velocity, and variety, retrieved from multiple sources and in various formats.

The Internet of Things (IoT) significantly contributes to generating big data sets.

Computing power and data handling advancements allow for complex analyses, aiding process optimization and predictive decision-making based on multiple data sources. This leads to better decisions, predictable outcomes, and higher profitability.

However, analyzing massive data amounts is meaningful only if it results in user-friendly, actionable insights.

Real-time data presented on handheld devices facilitates quick decision-making on the warehouse floor, replacing time-consuming paper reports and desktop applications. Future trends may transition to hands-free technologies like smart glasses and augmented reality for seamless data migration and analysis.

Blockchain

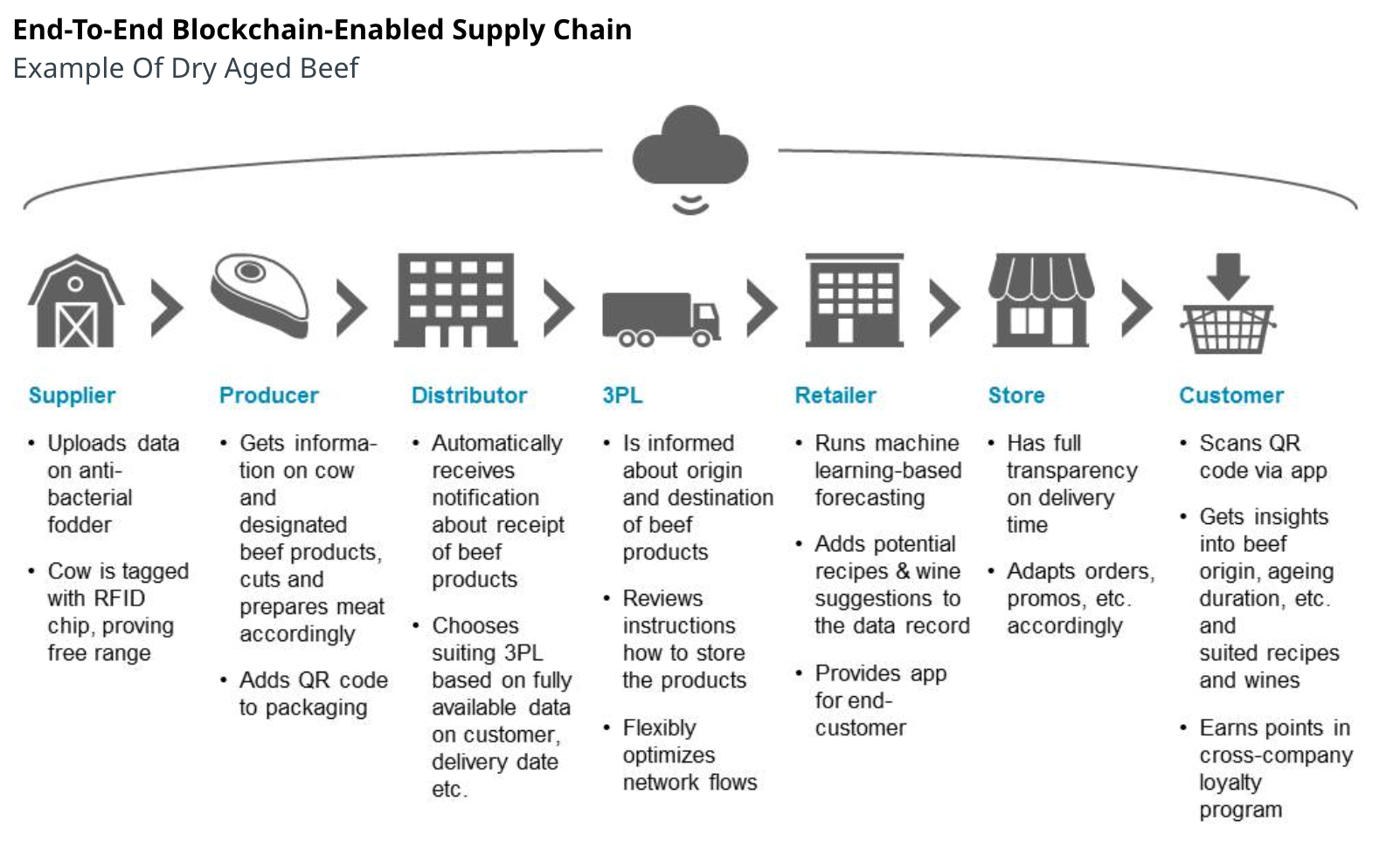

Blockchain is a relatively new concept and has been slow to catch on but is expected to play a bigger role not only in the warehouse of the future but in all aspects of business, finance, society, and government.

Blockchain is a public digital ledger of transactions that records information in such a way that the data is difficult to alter. Each time a transaction is completed it is independently verified by peer-to-peer computer networks, time-stamped, and added to a growing chain of data. Once recorded, the data cannot be altered.

Potentially the biggest benefit from blockchain in the distribution landscape is complete transparency to product sourcing and processes as inventory moves through the supply chain.

As product sourcing, lot tracking, and sustainability concerns grow, blockchain can provide validation of providers’ claims and allow for quick, precise identification of a product’s location in the supply chain.

Although the concept of blockchain was initially developed to support the cryptocurrency market, it has far more reaching potential. Since it is more of a foundational change in the way business will be done in the future and has a far-reaching impact, its widespread adoption may be decades away.

Warehouse Automation with Robotics

Some of the technology that is gaining traction in the retrofit and design of new distribution centers has been around for a while. Technologies such as automated storage and retrieval systems (ASRS) have been in use since 1962, while the first automated guided vehicle (AGV) was introduced in 1950, and the first robotic arm in 1962.

These technologies have undergone improvements or morphed into other versions (AGV → AMR) as the technology developed but their basic functionality remains the same.

These improvements were a result of more powerful computing systems which led to more sophisticated software programs resulting in better functionality, often at lower cost, so the return on investment for these technologies is now more appealing to more retailers.

Cost may now be secondary to labor availability as the key parameter for investment decisions.

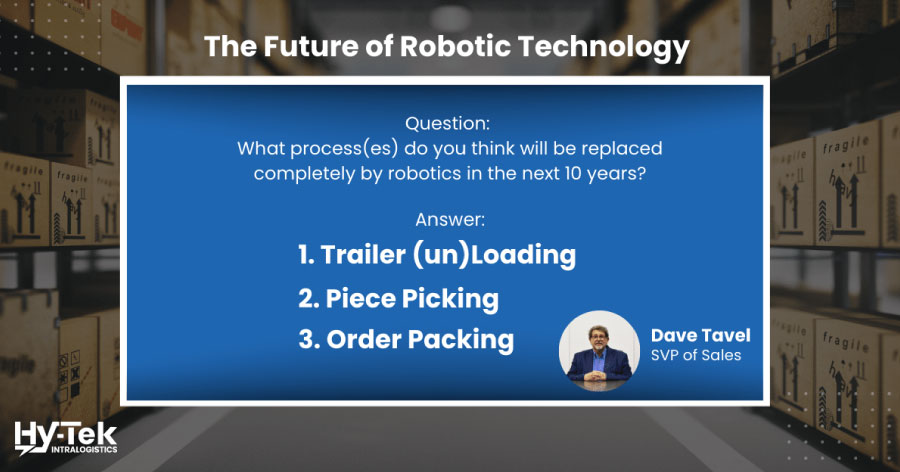

In the next 5 to 10 years, we are going to see less fixed automation in facilities. So fewer conveyors, and fewer sorters that cost millions of dollars and run 10,000 units an hour. You’re going to see a robotic sorter where they can add and take away robots to help manage peaks and valleys within the business.

3 areas where we can expect a fully-automated process in the next 5 to 10 years are:

Trailer loading and unloading:

The physically strenuous task of unloading trailers, which often exposes workers to harsh weather conditions, has been one of the least sought-after jobs in the warehouse. While automating this task was once thought to be a distant possibility, recent advancements suggest that it could become a reality. A combination of sensors, cameras, controls, and artificial intelligence (AI) direct robotic movements. Robots will be required to reach boxes throughout the entire trailer, handle boxes of different shapes and sizes, and react to configuration changes.

Piece picking:

Piece-picking robots pick products from inventory totes and place them into order containers or onto a conveyor. Historically, robotic piece picking has been difficult because of the wide range of product shapes, sizes, and weights, and designing an end-of-arm tool that replicates the sensitivity and versatility of a human hand has been very difficult.

To give an example, you’ve picked an order with 10 units and it’s going to a pack station. The person at the station would scan the tote to identify the order and tell them what carton to pack the order in. They would then pack and sometimes put void fill in it. This process is highly dependent on labor as it requires picking different carton sizes and handling unique objects in each tote.

In addition to the physical components of the robot, a very large factor in the success of piece-picking is the software’s capability to be able to identify and react to these variables.

Order packing:

While robotic advancements in picking things up are great, the task of putting things down is much more difficult. Why? For orders that have a higher number of items, such as orders for retail or wholesale fulfillment, items of varying shapes and sizes must be placed in a “Tetris” configuration.

As vision systems and packing algorithms advance, robotic order packing will be more feasible. The global packaging robots market size was valued at $4.3billion in 2020 and is projected to reach $14.4 billion by 2030, growing at a CAGR of 12.3% from 2020 to 2030

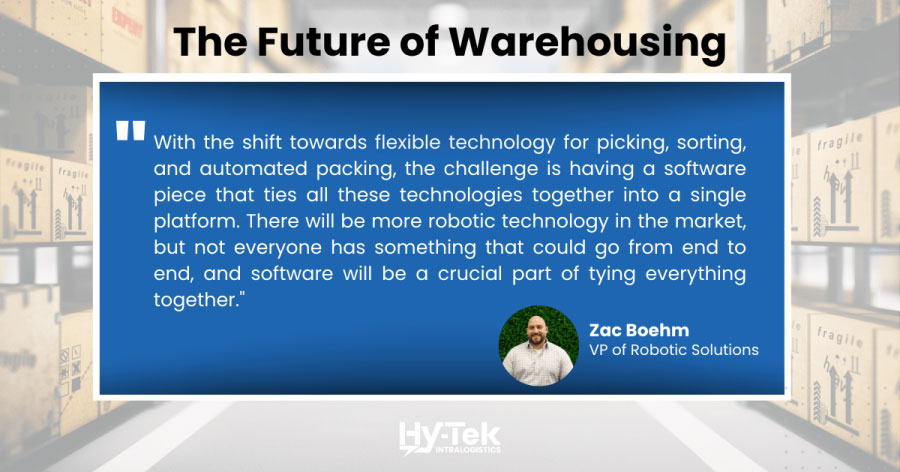

As the industry progresses with technology and robotics, more vendors will be in the marketplace. So, each of the original equipment manufacturers (OEM) will have their own software that runs that piece of equipment. The challenge this presents is that none of the manufacturers’ software communicates with each other, and you have siloed, ineffective communication.

The need for warehouse software that connects every system in your facility will become more and more important as more robotic vendors are utilized.

AI & Digitalization

As consumer demands get more stringent, so does the need for companies to increase the reactivity of their warehousing processes.

For companies to keep up with such high demands, they must increase the functionality of their warehouse management systems. We hear a lot about AI Artificial Intelligence and Digitalization of warehouses, but what exactly does that mean? That means the days of printing out orders and walking to each location to pick a product are no longer an efficient process.

The Importance of Software for Future Warehousing

In order to effectively handle the growing volume of data and harness its power, the utilization of a robust, full-stack software suite is imperative. This software system enables efficient data collection and analytics, allowing for maximized warehouse space utilization, purchasing power, and productivity in an ever-expanding eCommerce world.

The significance of data cannot be underestimated, as it is the foundation of knowledge and informed decision-making. While data has always been present in warehouses, capturing it in a timely manner to facilitate dynamic decisions has been a challenge.

However, merely collecting vast amounts of data is not enough. The key is to present the analysis results promptly and in a format that enables quick decision-making on the warehouse floor.

With the advancement of technology within warehouses, the generation of data will increase exponentially. Warehouse management system software has played a role in leveraging this data, but there are still numerous untapped opportunities that lie ahead.

By implementing a robust, full-stack software suite, businesses can unlock the full potential of their data, optimize operations, and adapt to the evolving demands of the eCommerce landscape.

This comprehensive approach to data management is crucial in ensuring long-term success and competitive advantage in the modern warehouse environment.

Smart Warehousing – What is it and how will it evolve?

Smart warehousing utilizes a comprehensive and complex set of tools to help manage and streamline the overall fulfillment and warehousing operations. Using smart technology allows you to leverage next-gen solutions to enable better decision-making, reduce overall operational costs, and allow you to be fully integrated to ensure internal processes are as efficient as possible.

Smart warehousing is predicated on data analytics. Data analysis allows an operation to have a granular view of the entire operation so that you can make informed decisions as it relates to labor, inventory management, shipment demands, etc.

Technologies, such as AS/RS, Internet of Things (IoT), automated picking tools, collaborative robots, warehouse management systems, smart replenishment, etc., will allow a company to fully leverage, utilize, and execute a smart warehouse strategy.

As our business landscape evolves and changes, there is greater pressure from the customer to ensure that just-in-time is not only met but that it is the expectation moving forward. Smart warehousing will be a pillar to support this evolution of customer demand. The days of shipping items within days and weeks are no longer acceptable in today’s market.

Customers have adjusted their behaviors and buying power to be met with items being delivered within hours of purchase, not days.

The pressure of satisfying customers’ buying behaviors and buying power, will continue to build and change the “on-demand” landscape to where smart warehousing will be paramount for operational success.

With all things, evolution is necessary for survival. Businesses will be forced to leverage innovative technologies to ensure they can be successful in this very demanding market. I see smart warehousing aggressively evolving in the next 2 to 5 years where the days of manual/traditional fulfillment give way to fully integrated solutions to meet operations ordering processes and needs.

Conclusion

In conclusion, the future of warehousing holds immense potential, driven by the continued advancements in automation technology. The rise of flexible automation is revolutionizing the way warehouses operate, offering unprecedented efficiency, adaptability, and scalability. As we look ahead, we can anticipate even more exciting developments in automation technology that will shape the warehouse of tomorrow.

With the advent of technologies like artificial intelligence, machine learning, robotics, and the Internet of Things (IoT), warehouses will become smarter and more interconnected. Intelligent systems will enable real-time data analysis, predictive analytics, and autonomous decision-making, optimizing warehouse operations and streamlining supply chain processes.

We can envision a future where fully autonomous robots collaborate seamlessly with human workers, creating a harmonious blend of human expertise and machine precision. Robotic arms, drones, and AGVs will navigate warehouses effortlessly, performing tasks with speed and precision, while human operators oversee and guide the automation systems.

Moreover, warehouse automation will extend beyond the four walls, integrating with external systems and networks. Collaborative platforms, blockchain technology, and cloud-based solutions will enable seamless information exchange and supply chain visibility, fostering efficient inventory management, order tracking, and customer fulfillment.

As automation continues to evolve, emphasis will be placed on sustainability and environmental responsibility. Energy-efficient systems, renewable energy integration, and waste reduction initiatives will shape the future warehouse, creating greener and more sustainable operations.

In this future landscape, warehouses will become agile hubs of innovation, constantly adapting to changing market dynamics and customer dem