Slotting a warehouse or distribution center might seem like a simple aspect of inventory management that has little impact on your operation’s efficiency. However, poor slotting can derail an operation. Wasted time from unorganized pick paths can wreak havoc on the overall productivity of an operation and poorly located product can cause an increase in fatigue for your associates (and even increase the potential for injury).

Optimizing a warehouse’s slotting can provide an operation with a productive boost with tangible results. Below, we will cover five tips for optimizing your warehouse’s slotting profiles and bringing those tangible results to your operation.

What is Warehouse Slotting?

Warehouse slotting is to the process of strategically organizing and assigning storage locations for inventory items based on factors like product characteristics, demand patterns, and operational efficiency.

Why is Slotting Important?

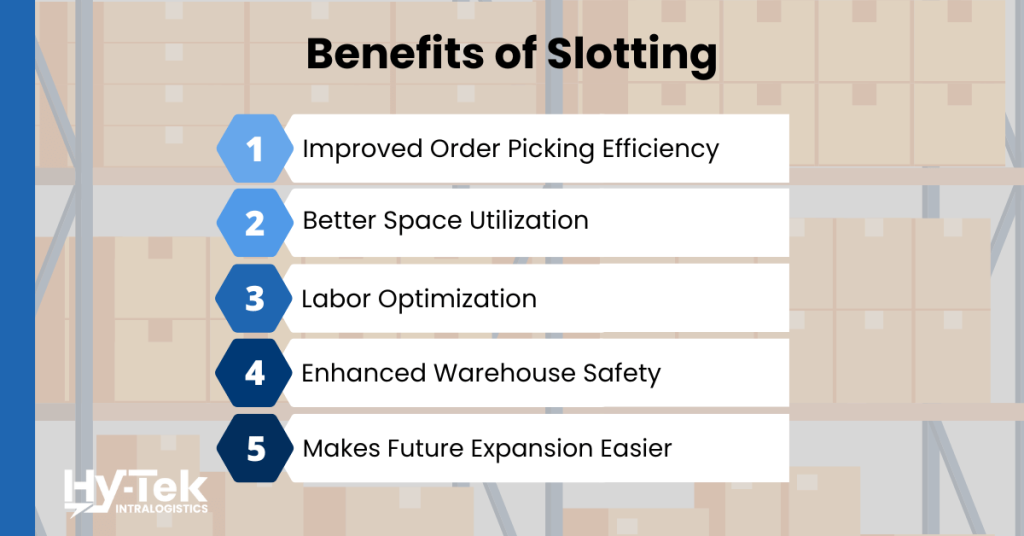

Efficiently slotting a warehouse is crucial for optimizing operations and maximizing productivity. By organizing inventory in a strategic manner, businesses can minimize unnecessary labor and storage costs, enhance order fulfillment speed, and improve overall warehouse performance. Here are some key reasons why slotting your warehouse is important:

- Improved Order Picking Efficiency:

- Reduces travel time and minimizes unnecessary movement within the warehouse.

- Enhances order accuracy by locating products in logical and easily accessible locations.

- Facilitates faster order picking, packing, and shipping processes.

- Space Utilization:

- Maximizes storage capacity by utilizing available space more effectively.

- Enables the implementation of efficient storage systems, such as slotting products based on size, weight, or turnover rate.

- Helps in identifying and utilizing dead or slow-moving inventory.

- Labor Optimization:

- Streamlines warehouse operations by reducing time spent searching for items.

- Minimizes employee fatigue and increases productivity.

- Enables effective labor planning and resource allocation based on slotting strategies.

- Enhanced Warehouse Safety:

- Organized storage minimizes the risk of accidents caused by improperly stacked or misplaced items.

- Ensures clear pathways and safe access to emergency exits.

- Facilitates compliance with safety regulations and standards.

- Scalability and Growth:

- Enables efficient handling of increased order volumes and future expansion.

- Simplifies warehouse reconfiguration and layout changes as the business evolves.

- Facilitates the integration of automation and technology solutions for improved efficiency.

By considering these benefits and implementing effective slotting strategies, businesses can optimize their warehouse operations, reduce costs, and deliver better customer service.

How to Slot Items in Warehouse

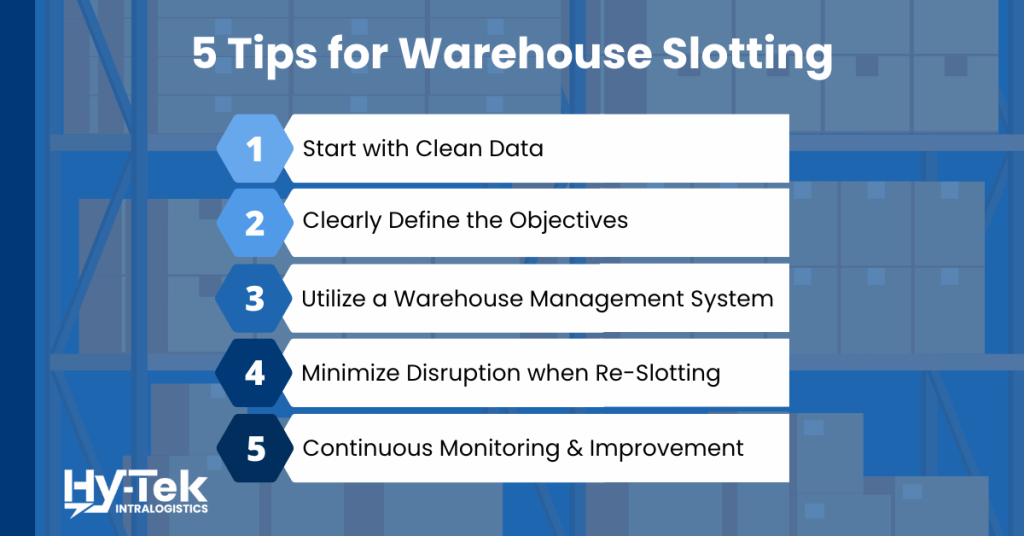

Warehouse slotting is an extremely useful strategy. Here are 5 tips to start and maintain an optimal slotting strategy:

1. Start with Clean Data

Clean data is the foundation that every slotting model must be built on. If there are any qualms about the validity or veracity of your dataset, then steps need to be taken to ensure you are working with the best available information. During the cleansing process, ensure that there are no “dummy values” hidden in the data.

Important data fields when slotting include item velocity (number of hits or total lines in a time period), and required on-hand levels (how many days’ worth of stock you would like to hold in a pick location), with the most important being item dimensions and weights.

Grabbing accurate dimensions and weights and continually updating the SKU Master list can be accomplished during the inbound process – especially with the use of technology such as a Cubiscan machine.

2. Clearly Define the Objectives

When re-slotting a facility, it is important to establish the rules that you want to use to drive your methodology. Clearly defining these parameters – such as zoning (sometimes called “golden zoning”), matching pick velocity to the storage medium (i.e., bulk pallet locations or flow locations), SKU consolidation for better space utilization, and special categorizations (i.e., hazmat, fragility, etc.) – can all be then factored and allow you to produce the optimum pick paths.

3. Utilize a Warehouse Management System

A warehouse management system (WMS) plays a crucial role in efficiently slotting a warehouse and optimizing its operations. With its advanced functionalities and features, a WMS can provide businesses with the tools they need to implement effective slotting strategies. Here’s how a WMS can be used for slotting:

- Product Profiling: A WMS allows businesses to categorize and profile their products based on various attributes such as size, weight, demand, or shelf life. This information helps in determining the most suitable slots for each item.

- Slotting Optimization Algorithms: WMS platforms often include advanced algorithms that analyze data and recommend optimal slotting configurations. These algorithms consider factors like product velocity, order patterns, and storage constraints to suggest the best slotting locations for each item.

- Slotting Rules and Constraints: A WMS enables businesses to define slotting rules and constraints based on their specific needs. These rules can be customized to align with storage capacities, product characteristics, or operational requirements. For example, perishable goods may require slots near refrigeration units.

- Dynamic Slotting: A WMS allows for dynamic slotting, enabling businesses to adapt their slotting strategies in real-time. When inventory characteristics or order patterns change, the system can automatically adjust slotting configurations to optimize efficiency.

- Reporting and Analytics: A WMS provides valuable insights into slotting performance through reporting and analytics. Businesses can analyze metrics such as pick rates, travel distances, and labor utilization to identify areas for improvement and make data-driven decisions.

4. Minimize the Disruption when Re-Slotting

Re-slotting can be a tedious task – especially when an operation must continue to run with its normal workload. Once the re-slotting output has been finalized, establish an execution plan that minimizes the effects on the normal operations and prevents downtime. Performing these moves during non-productive hours can help to minimize disruptions to the operation. As the stock is moved, it is also important to cycle count all affected SKUs to minimize the risk of a reduced inventory accuracy percentage.

5. Continuous Monitoring and Improvement

A warehouse’s slotting plan is never finished! It is always a prime candidate for continuous monitoring and improvement, especially as business factors change. Seasonal promotions, peaks, and the associated ramp-up in on-hand stock can push SKUs to different slot types or locations. Getting stuck in a status quo is a sure-fire way to introduce inefficiencies to your operation, so there should be no hesitation in starting a re-slotting project.

Slotting is an important aspect of any warehouse’s operation. If you believe that your operation could benefit from a re-slotting project, do not hesitate to contact a consultant today for any needs you might have!