For your supply chain to be flexible and scalable in today’s market, Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS) software are necessary for capturing data and automating business processes.

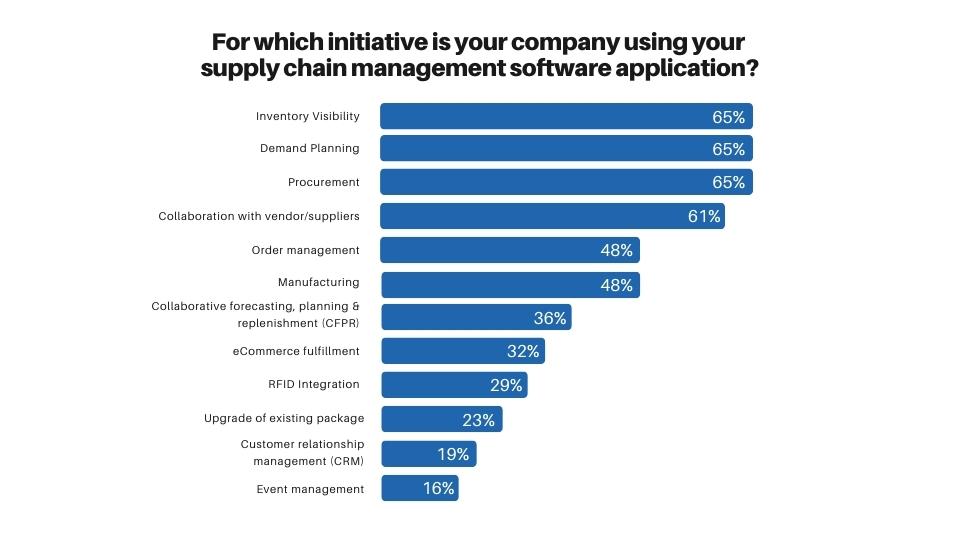

Based on a report by Peerless Research Group, the top 3 supply chain initiatives for which businesses are utilizing a software application are 1) Inventory Visibility, 2) Demand Planning, and 3) Procurement.

ERP and WMS can help accomplish most of these initiatives, and it is common to use the two terms interchangeably. However, there are a few key differences.

Before choosing to implement one over another, you must fully understand the core functions of each to avoid incurring additional costs in the future.

What is an ERP System?

Enterprise Resource Planning (ERP) System is a business management software that collects, stores, manages, and interprets data related to accounting, procurement, project management, risk management and compliance, and supply chain operations. It has some functional overlap with a WMS, however, ERP systems prioritize accounting and financial data.

An ERP system usually includes a variety of integrated modules that give more visibility to data pertaining to a variety of business functions:

- Sales

- Procurement / Purchasing

- Manufacturing

- Marketing

- Finance / Accounting

- HR

- Inventory management

- Shipping

The capabilities of enterprise resource planning (ERP) are similar to those of warehouse management systems (WMS), such as tracking the status of inventory that is picked, packed, and shipped.

What is a WMS?

A Warehouse Management System (WMS) is a software system that captures, stores, and analyzes data that is generated as goods and material flow in and out of your warehouse.

For example, a WMS can generate reports based on historical trends that detail the optimal pick location for every SKU.

A WMS captures data pertaining to:

- Sales

- Order fulfillment

- Shipping

- Replenishment

- Inventory

- Racking

- Manufacturing raw materials

All of these operations and data must be tightly integrated as part of a complete supply chain management strategy. There are many benefits of a WMS – it drives responsiveness, makes critical decisions, and executes those decisions based on real-time data.

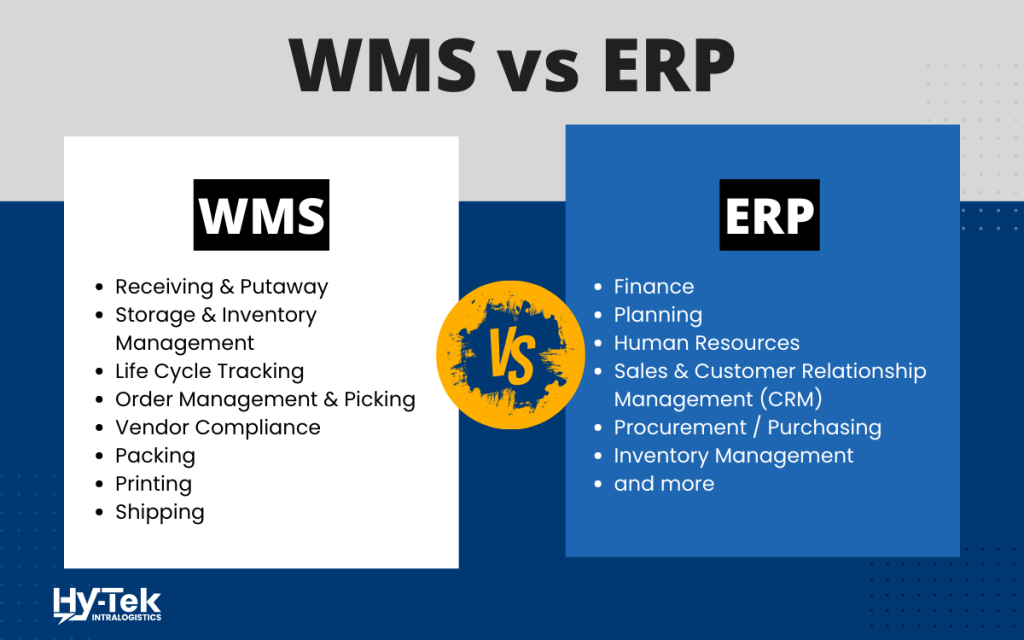

WMS vs ERP

The main difference between ERP and WMS software is that ERP is primarily accounting software that automates processes across the business and analyzes operations against the bottom line. A WMS is specific to inventory and warehouse data, and it provides optimization insights for the movement and storage of inventory based on real-time information.

In terms of warehousing and inventory management, WMS vs ERP is essentially the same as inventory management vs. inventory accounting.

An enterprise resource planning software is primarily utilized by CFOs or financial executives to analyze inventory related to high-level accounting decisions (i.e. profits, loss reports) rather than the granular, detailed optimizations that a WMS can provide to supply chain oversight.

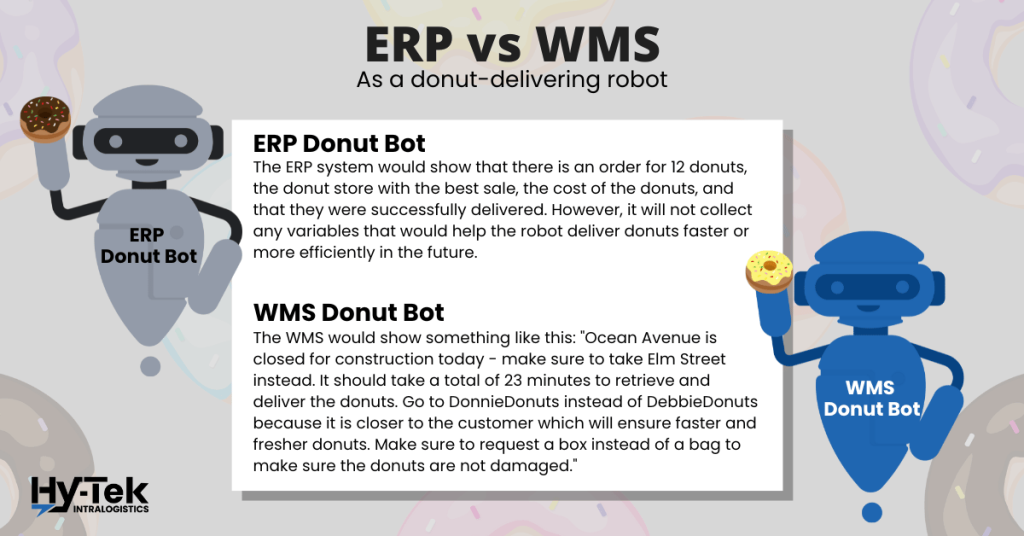

Let’s say we have a donut-delivering robot.

The ERP system would show that there is an order for 12 donuts, the donut store with the best sale, the cost of the donuts, and that they were successfully delivered. However, it will not collect any variables that would help the robot deliver donuts faster or more efficiently in the future.

The WMS would show something like this: “Ocean Avenue is closed for construction today – make sure to take Elm Street instead. It should take a total of 23 minutes to retrieve and deliver the donuts. Go to DonnieDonuts instead of DebbieDonuts because it is closer to the customer which will ensure faster and fresher donuts. Make sure to request a box instead of a bag to make sure the donuts are not damaged.”

True WMS vs ERP Modules – Which is Better?

There are many types of warehouse management systems that can be deployed, and adding to the confusion, is many ERPs have started to offer a WMS module as part of their core system. The advantage of this is an all-in-one system with easy integration alongside the ERP.

But can the ERP’s WMS module functionality hold up over time and be able to scale with your business growth? These modules are add-ons to the original software which means that the original software was not built to incorporate these add-ons, leaving you with a patchwork of modules that integrate but are not seamless.

Scalability and flexibility become more and more difficult over time when utilizing ERP WMS Modules.

For some small to mid-sized businesses, there are situations that the ERP WMS module can be just what you need. If you are a small distributor with a highly predictable operation and have 5 or fewer warehouse employees, an ERP WMS module could be sufficient.

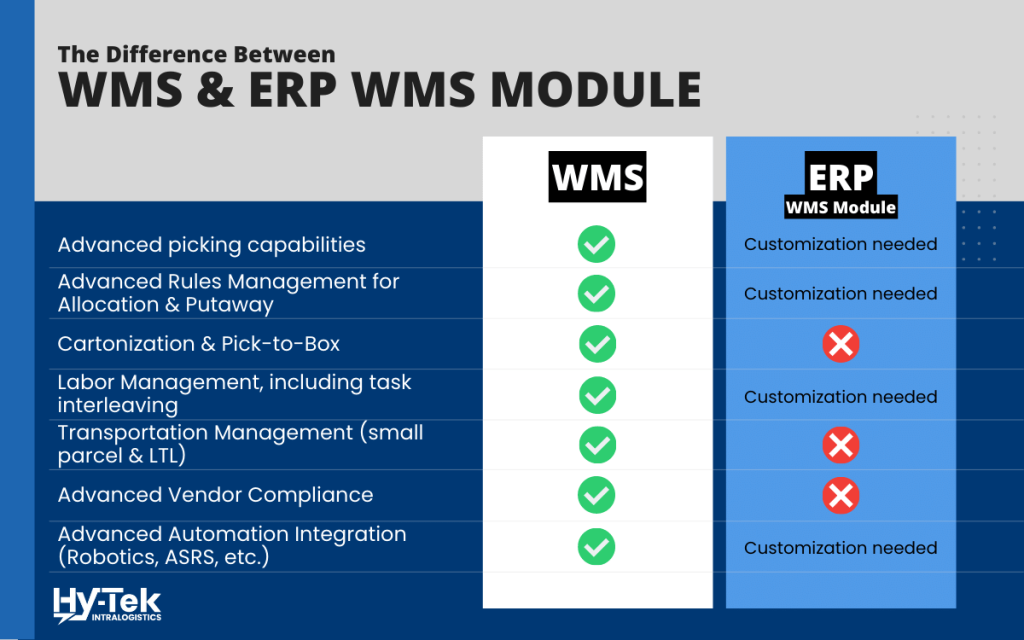

But beyond this, there are more than a few considerations when deciding to deploy a true WMS or an ERP WMS module:

- Picking – With a true WMS, you will have ultimate picking flexibility. Need to improve productivity and capacity? Adopting a new picking method like voice-directed picking or pick-to-box will allow you to tailor your needs to your operations, and a true WMS can make these transitions seamlessly. Many ERP WMS modules, however, will restrict your options to only a few methods or just one.

- Putaway – Putaway is integral to inventory control and with a true WMS, you’ll have advanced putaway logic with the ability to create defined rules allowing for smart use of floor and rack space, as well as manage a high number of SKUs across multiple zones. With an ERP WMS module, putaway is typically limited to only one primary location.

- Task Management – Using a true WMS, you can take advantage of a high level of work prioritization. In addition, it can have the same worker directed to perform a variety of task types, rather than repeating the same task over and over. This practice is referred to as “task interleaving”. This can alleviate wasted movements and assure that orders leave the warehouse on time. In contrast, most ERP WMS modules have limited prioritization functionalities, and most do not offer task interleaving.

- Reporting and Dashboards – One of the most important aspects of a successful warehouse operation is the availability of real-time data and reporting for measuring success and finding opportunities to improve. A true WMS can provide multiple dashboards that show operational data to managers and the warehouse floor. Many also offer this information on a web basis, so you can check operations no matter where you are in the world. Many ERP WMS modules do not offer any real-time data or reporting based on historical trends.

- Advanced Capabilities – ERP WMS modules are at a loss when it comes to advanced capabilities, the following functions come standard with many true WMS systems: transportation management, dock scheduling, advanced vendor compliance, labor management, and advanced automation integration (robotics, AS/RS etc.)

A WMS of any type will improve the operations of businesses that are not currently using one. They can improve efficiency and reduce costs across the warehouse. However, opting to use an ERP WMS module due to ease of integration or cost, instead of a true WMS, can limit a company’s ability to be flexible within their operations, as well as restrict growth.

WMS or ERP for Omnichannel Fulfillment

More and more companies are utilizing omnichannel fulfillment in the supply chain to be closer to the customer. It’s necessary to utilize a software system (or a suite of software solutions) that can accommodate this complex fulfillment method and optimize the flow of information.

Typically, businesses will utilize both a WMS and ERP for omnichannel operations.

WMS provides data at the warehouse level, not at the global supply chain level. An ERP provides information across all channels. WMS typically does not track orders once it leaves the warehouse which means an ERP is necessary to communicate to all channels that the order is in transit.

Conclusion

Today’s complex supply chain operations must be well-choreographed to generate, feed, process, update, receive, and disseminate information at every stage. From sales, order fulfillment, shipping, replenishment, inventory, tracking, finance, and beyond, all areas must be part of a complete warehouse management strategy. A tightly integrated software must deliver the level of visibility, control, and responsiveness needed to support such a strategy.

There is an overlap between the functionalities of a WMS and ERP. However, in terms of scalability and inventory management, WMS proves to provide more granular information and provide useful insights that allow you to optimize your supply chain.

Using a Warehouse management system (WMS), no matter the type or functionality, is a must for success in any operation. However, choosing the right WMS for your business, today and in the future, can be a complicated exercise. You have to understand what software is the right fit, at the right price point and at the right ROI.

A WMS will improve efficiency and reduce costs across warehouse operations. However, opting to use an ERP WMS module due to ease of integration or cost, instead of a true WMS, can limit a company’s ability to be flexible within their operations, as well as restrict growth.

When choosing which route is best for you, it is important to first understand your business needs and to work with a WMS and ERP expert. If you already have an ERP in place, WMS modules may be the better option versus implementing a standalone WMS, but it depends on your business case.

FAQ

What is the difference between ERP and WMS?

ERP is primarily accounting software that automates processes across the business and analyzes operations against the bottom line. A WMS is specific to inventory and warehouse data, and it provides optimization insights for the movement and storage of inventory based on real-time information.

Can a WMS be integrated with an ERP?

Yes, ERP integration is a key feature of Hy-Tek’s WMS software.