A robotic systems integrator chooses the best robots for your warehouse and installs them. They will make sure all systems (conveyors, sorters, GTP robots, mobile robots, WMS, WCS, WES) work cohesively as one unit. The integrator will come up with an automation plan, and oversee the implementation and testing processes to ensure your improvement goals are met.

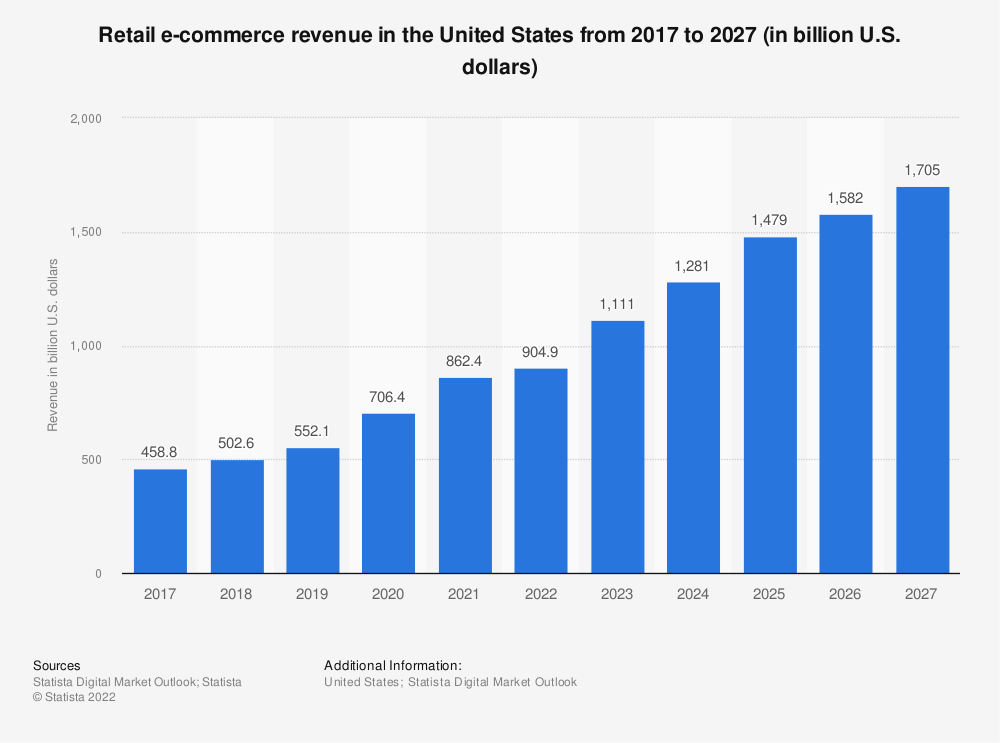

When it comes to implementing new robotic systems or updating existing ones, working with a robotic systems integrator is the best way to ensure a smooth and successful integration. As e-commerce and online retailing continue to grow, the need for warehouse and facility automation will become even more essential, while keeping costs and operational complexity under control.

An integrator is a very important role in material handling, as improper implementation of new robotics and automation solutions can lead to decreased efficiency and productivity.

Benefits of Robotic Systems Integrator

System integrators understand how all of the various automation solutions and robotic systems in a facility operate versus each system manufacturer only specializing in its own product.

Therefore, working with a system and robot integrator can ensure that all of the solutions work together. This minimizes downtime and increases operational efficiency.

Here are a few ways that integrators improve operations by integrating robotics:

- Identify and suggest the appropriate robot based on an analysis of your requirements and goals

- Can help to increase process efficiency

- Can help to improve quality control and accuracy

- Improved system reliability

- Minimize system downtime

- With our years of expertise, we can provide you with cost-saving suggestions

- Streamlined & automated exchange of information between systems is more reliable and efficient

Here’s an example. A company wants to add robots to its packaging line. The robotic systems integrator would work with the existing conveyor system to make sure the two systems are compatible and able to communicate with each other. They would also program the robots to work in harmony with the rest of the packaging line.

The above example shows how important it is to work with a robotic integrator, as they are the only ones with the knowledge and experience to properly implement new robotic systems.

Robotic Systems Integration Process

Our 6-Step process ensures that your project’s entire lifecycle will stay on track to achieve your organization’s goals of strategy, time, money, and ROI. We will optimize supply chain operations, enhance employee productivity, and maximize your return on investment by carefully managing years of expertise with successful planning and implementation.

Assess

During the assessment stage, we will visit your site to perform a thorough examination of your needs, and we will provide you with a detailed proposal that identifies the project scope.

Analyze

After the assessment stage is complete, our team will analyze your data of current processes. This will be the baseline measurement of success.

Recommend

After the analysis stage, our team will recommend a system that will best fit your needs. We will provide detailed recommendations, layouts, timelines and budgets.

Approve

We will meet with the entire executive team to outline our path forward and ensure that we are aligned with your goals. Our team creates a roadmap for the project. We will develop timelines, milestones, and tasks that need to be completed.

Implement

We will coordinate and manage all aspects of the project and ensure that the system is performing cohesively within your overall operation.

Support

We will analyze the success of the implementation from the baseline data we collected and provide a detailed performance analysis report whether your goal was to increase accuracy, reduce labor, or increase order cycle time.

Top 5 Types of Robotic Systems We Integrate

- Goods-to-person systems

- Autonomous Mobile Robots

- (De)Palletizing Robots

- Pick and Place Robots

- Robotic Sortation Systems

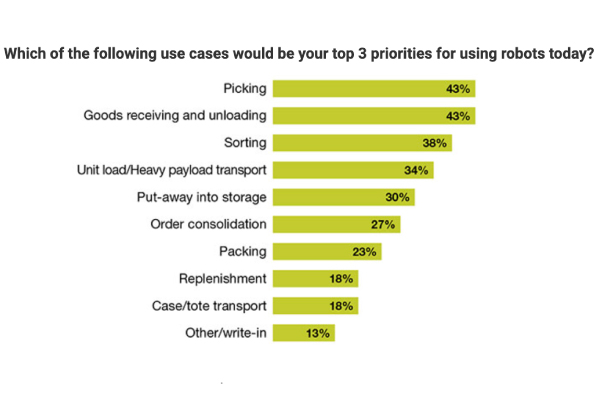

According to a study, the processes outlined in the chart below are how companies are prioritizing robotic automation in their facilities. The systems that we integrate are to assist in these operations.

What Robotic Systems Do We Partner With?

- Exotec

- Caja

- Berkshire Grey

- Nipper

- Mobile Industrial Robots (MiR)

- T-Sort

- Autoguide

- Universal Robot

Common Industries

- eCommerce

- Retail

- Pharmaceutical fulfillment

- Third-Party Logistics Providers

- Grocery fulfillment

- Food & Beverage

- Manufacturing

- Wholesale

Why Choose Hy-Tek Intralogistics as a Robotic Integrator?

The integration division of Hy-Tek has been developing best-in-class fulfillment and distribution solutions for a range of industries and clients for more than 45 years by combining the power of creative design with a strategic choice of equipment manufacturers.

As a client and project partner of Hy-Tek, you can expect to receive individualized attention and time from an expert, niche partner. Hy-Tek Intralogistics can handle every aspect of the supply chain, from strategic planning to system implementation across your supply chain.