Experience Unmatched Modularity & Scalability

Whether you need more control or better control of your material handling systems, the Realtime360 Warehouse Control System™ offers you a complete WCS solution. From sortation and in-motion weighing to label print and apply and PLC controls, our solution offers both the modularity and scalability to fit your needs, coupled with the most user-friendly HMI available.

Key Features

01

Fully compliant with all industry standards from the floor to the host system

02

IT friendly, database-driven software application at the core of the system

03

Scalable, email alerts, front-end graphics, tablet friendly

04

Remotely accessible web-based reporting

Need Better Control of your System?

Improve your business operations with the modularity and scalability you need.

This introductory eBook discusses crucial warehouse software to help you optimize your warehouse space, reduce inventory costs, increase order fulfillment rates, avoid stockouts, and more.

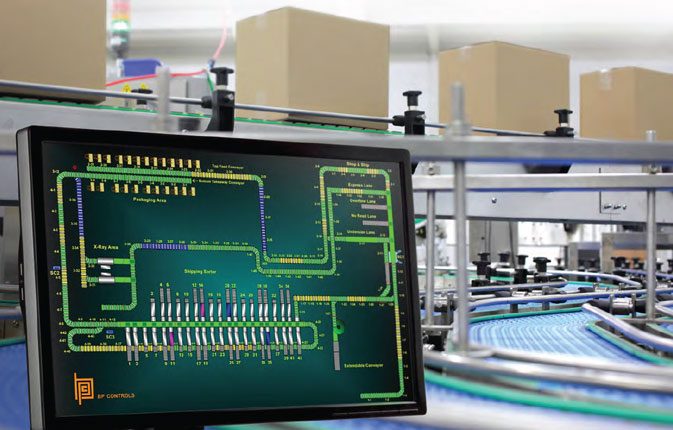

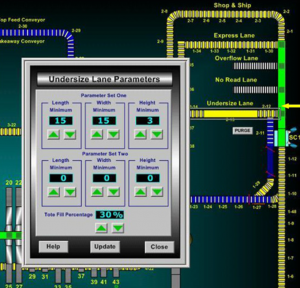

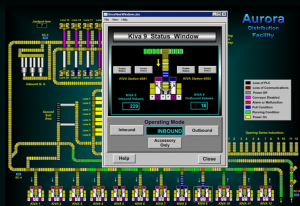

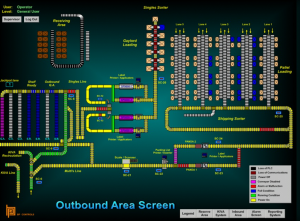

HMI & Diagnostics Reporting

Innovative HMI (human-machine interface) based on CAD layout of your systems provides a user-friendly GUI (Graphical User Interface) that enables easy set-up and operation

- Configurations

- Operations

- Maintenance

- Performance Reporting

Easy adjustment of multiple operational parameters. HMI provides a real-time view of each material handling system.

HMI enables real-time monitoring of all WCS systems allowing adjustment as needed.

Real-time view of WCS systems. Color-coded operational status for easy troubleshooting and quick problem resolution.

Provides easy to understand diagnostics and reports on system performance.

Specific Items Monitored*:

- Status of each electrical panel (Emergency-Stop, Power and Overload faults)

- Battery condition from each PLC (Normal, Low)

- PLC status (Major Faults, Scan Time, Rack Conditions)

- Air Pressure status from each compressor (Normal, Low)

- Motor overload status by panel

- Jams, Full Lines and Emergency-Stop Status by panel

- Individual Motor Status

- Individual Full Line and Jam Photoeye Status

- Individual Emergency-Stop Pushbutton/Lanyard Status

- Total Cartons Scanned

- Total Cartons Confirmed

- Total No-Read Count

- Total Reject Count

- Total Re-circulated Count

- Percentage of Valid Reads

* Realtime360 View is built upon our standardized software platform and tailored to the various systems being monitored. Because it is configured specifically for each application, all functionality described above may not be included in your system.

Automation Control System

A PLC platform for controlling and monitoring inputs and outputs (I/O) for various material handling applications. Whether the industrial control system consists of a single motor or hundreds, we provide the right solution for your needs. This system integrates seamlessly with the entire WCS offering, including automatic sortation, host communications, production counting, and our HMI and diagnostics warehouse software.

01

Provide conveyor controls on the PLC platform for various applications

02

Standard system supports from one (1) sort destination up to 1000

03

Interfaces to our WCS package for system status, maintenance, and reporting functions

04

Functions as a stand-alone system or connects with other PLCs and PC sub-systems

05

Communicates with third-party WCS and HMI packages

06

Interfaces and Controls all 24VDC & 48VDC Motorized Roller Ethernet Cards