The Exotec Skypod system is an agile and high-performing automated order preparation designed for businesses that need an efficient, scalable and responsive goods-to-person solution for order fulfillment or returns.

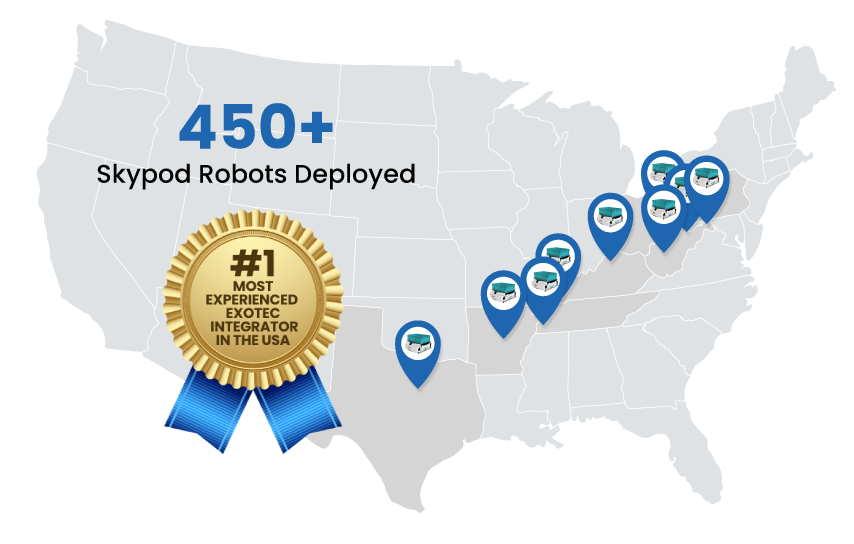

Experience Matters

Our team has proven implementation success of the Exotec Skypod System, enabling us to:

- Anticipate and mitigate potential challenges

- Ensure system reliability

- Rapid deployment

- Minimal downtime

- Cohesive system integration with existing technologies

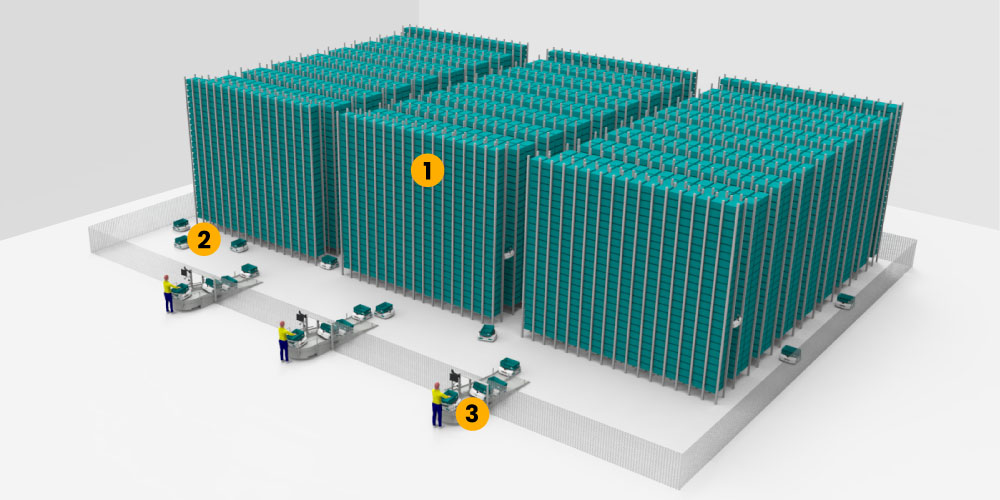

How It Works

The Exotec Skypod automated warehouse picking system is the first of its kind to use 3D mobile robots that can move in three dimensions. Laser scanner navigation and AI allow the Skypods to navigate in a multidirectional manner, carrying 66 lb. bins, freeing up time for the warehouse team members to focus on packing and shipping, avoiding long-distance walks to access inventory.

Completely passive and made of simple racking and bins, Exotec’s high-density automated warehouse picking and storage system maximizes facility space without sacrificing bin accessibility.

The bins can be segmented in compartments of 2, 4, 6 and 8 to hold a variety of SKUs.

Trays can also be utilized to hold cases/cartons.

Exotec’s high-density automated warehouse picking and storage system maximizes facility space without sacrificing bin accessibility.

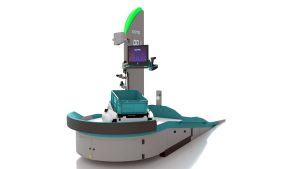

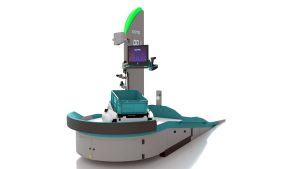

Skypod Robot

As the only moving part, the Skypod is the core of the Exotec system.

The Exotec Skypod is a light robot that can move in all directions. The autonomous robots are programmed to retrieve and store bins from storage locations while the operator stays at the workstation for final order assembly.

Workstations

The ergonomic work station is equipped with a ramp, a screen, and several scanners to facilitate operators in picking up to 400 lines per hour.

This setup accommodates robots equipped with bins and trays, which are conveniently presented to the operators.

These stations have versatile applications such as order picking, inventory replenishment, and inventory checking.

Storage

Completely passive and made of simple racking and bins, Exotec’s high-density automated warehouse picking and storage system maximizes facility space without sacrificing bin accessibility.

The bins can be segmented in compartments of 2, 4, 6 and 8 to hold a variety of SKUs.

Trays can also be utilized to hold cases/cartons.

Exotec’s high-density automated warehouse picking and storage system maximizes facility space without sacrificing bin accessibility.

Workstations

The ergonomic work station is equipped with a ramp, a screen, and several scanners to facilitate operators in picking up to 400 lines per hour.

This setup accommodates robots equipped with bins and trays, which are conveniently presented to the operators.

These stations have versatile applications such as order picking, inventory replenishment, and inventory checking.

Skypod Robot

As the only moving part, the Skypod is the core of the Exotec system.

The Exotec Skypod is a light robot that can move in all directions. The autonomous robots are programmed to retrieve and store bins from storage locations while the operator stays at the workstation for final order assembly.

See Exotec in Action!

Test your products and application in our 25,000 square-foot Innovation Lab that houses several industry-leading robotic technologies.

Benefits

-

Scalable Storage

With Exotec's cookie cutter design, it is easy for our team to scale the system to the size and throughput needed.

-

Highly Order Reactive

With random putaway, the Skypods are able to access any tote in under 2 minutes, making the system highly order-reactive.

-

Quickly Accessible SKUs

Exotec's random put-away functionality allows the Skypod to place totes in the rack in the same vertical movement as its next pick.

-

Seamless Integration

The Hy-Tek team ensures that the Exotec system seamlessly integrates with existing infrastructure and software, minimizing disruptions and facilitating rapid deployment.

-

Optimized Space Utilization

When utilized at the maximum height of 39 feet, the racks provide up to 5X more storage than non-automated storage solutions.

-

No Single Point of Failure

The Exotec System will dynamically reassign the robot fleet to seamlessly complete order fulfillment.

Proven Experience

Our team has a deep understanding of the intricacies of the Exotec Skypod System as well as proven implementation success, enabling us to anticipate and effectively mitigate potential challenges.

When system reliability and uptime are a must, the decision to select an integrator with a proven track record and extensive experience becomes a clear choice.

Our implementation history enables us to devise effective strategies for future projects that optimize system performance and productivity.

Specifications

- Maximum Rack Height: 40 feet

- Maximum Station Throughput: 400 bins per hour (on a station operated by a human)

- Skypod Robot Speed: 4 m/s on the ground, 1.5 m/s climbing the rack

- Battery Charging: Skypods opportunity charge 5 minutes of every hour

- Tote Sizes: 8, 12, or 16. Using plastic dividers, totes can be divided into 2, 4, 6, or 8 compartments to store a variety of SKUs.

Applications

Retail

eCommerce

Food & Beverage

Manufacturing

3PL

Pharmaceutical

Wholesale

See Exotec in Action!

Test your products and application in our 25,000 square-foot Innovation Lab that houses several industry-leading robotic technologies.

Related Resources

Stay up-to-date with industry and product updates by subscribing to our monthly newsletter.